During the final development stages of the RH300B amplifier a

similar schematics for use with 2A3 tubes has imposed itself as quite feasible

and logical. The 2A3 is a DHT tube just like the 300B, of similar general

characteristics: mu is around 4 in both cases, while plate resistance is

between 700 and 800 ohms. The main difference between these two tubes, heaters

voltage aside, is maximum ratings – dissipation and voltage. Thus slight

downscaling of operating voltage and current to create operating conditions

acceptable for 2A3 tubes has been done before with several popular schematics.

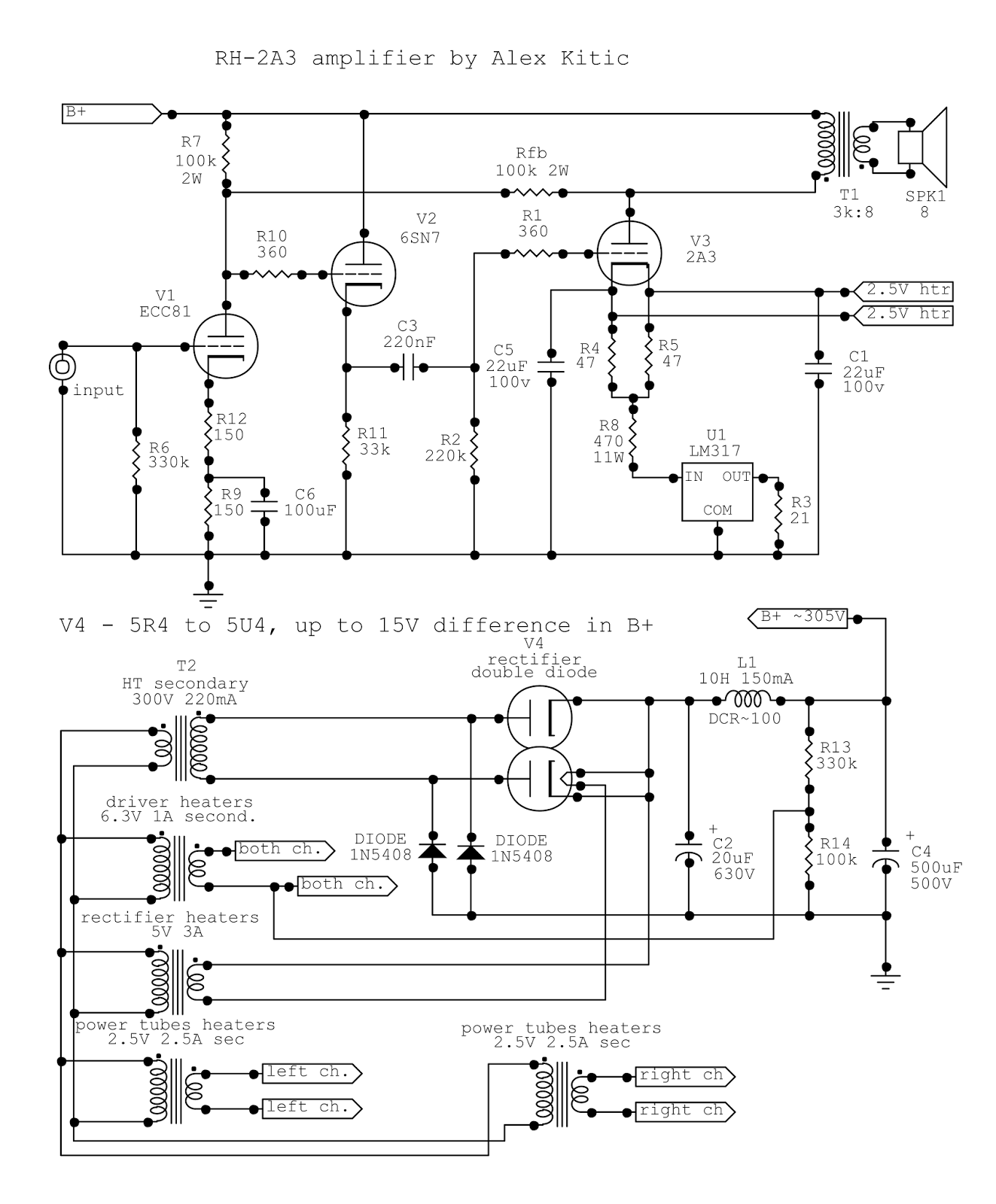

This would be the general RH2A3 schematics – almost a

mini-RH300B. With lower B+ and current consumption, cheaper to build due to

lower power requirements, different heater voltage for the output tubes, and

lower power with the same or similar output transformers. Just as in the case

of the RH300B, at 5.1W and 1% distortion, output power exceeds expectations –

and will probably be discussed and questioned in the future by all who have not

built the amplifier themselves and thus ascertained whether the promise has

been fulfilled.

As the schematics is strikingly similar to the RH300B, I shall not repeat all considerations related to the schematics itself – the only

appoint that should be made, or rather repeated, is that the operating point of

the cathode follower tube is determined by the directly coupled grounded

cathode driver tube. Thus it will draw the same current regardless of tube type

used – and this time I have chosen to adopt an octal socket, accommodating 6SN7

tubes, but 6SL7, ECC35, and other similar tubes can be used as well – you can

go as far as 6BL7, 6BX7… even 6AS7 (or 5998). While it might elude logic to

employ 6AS7, 6080, or 5998 (WE421 by TungSol) due to the relatively low current

draw, and keeping in mind that these tubes have very high heater current

requirements which would have to be taken into account – the sonic results

obtainable with these tubes reflects their known sonic characteristics, and are

quite interesting in the scope of this amplifier.

The twist

The RH2A3 can be built with regular 2A3 tubes, either NOS or

current production: it seems that just like the current production of 300B,

modern 2A3 tubes are good sounding, reliable, and meet the “single anode”

construction so much sought after by some DIY-ers and audiophiles. And of

course, that is the most logical way to go…

But I have built mine with “unusual” 2A3 tubes – on octal base.

While the 2A3 tube was manufactured as well with 6.3V heaters and UX4 base

(6A3), and further developed into a version with 6.3V heaters and octal base

known as 6B4G – I am referring to “special edition” 2A3 tubes, with 2.5V

heaters, mounted on octal base. The most notable application of these tubes have

been the Audio Innovations First and Second amplifiers, as it seems that 2A3

tubes were custom ordered on octal base due to a lack of UX4 sockets at the

time. In my personal opinion, while this is a plausible answer, I guess that

commercial concerns were important as well, channeling the supply of spare

tubes for the amplifiers.

Anyway, a different base just needs a particular socket, and

besides complicating life a little bit trying to source 2A3 tubes on octal

bases, this would not be much of a twist. In keeping with the inherent universality of my designs, at this

point the 1619 enters the stage. The 1619 is a direct heated beam tetrode tube

on octal socket. It has 2.5V heaters just like the 2A3, and is pin-compatible

with the octal socket used for octal 2A3 tubes – pins 2 and 7 for the

filamentary cathode, 3 for the anode, and 5 for the control grid.

So far so good - but what about the second grid and the beam

forming plates? While the 1619 is used by some in triode configuration, with g2

connected to the anode – this application is almost reserved for the old radio

collectors market. The 1619 is seen as a cheap replacement for expensive 45

tubes, and relatively elaborate adapters are being made or sold to allow

plugging the 1619 in old radio receivers. In the case of the RH2A3/1619

amplifier, the second grid on pin 4 is connected via a zener diode to B+ (56V 5W zener recommended, setting the g2 voltage at approximately 250V), while

the beam forming plates (pin 8) are connected to the shield (pin 1) and

directly to ground. Furthermore, pin 6 – which is missing on 1619 tubes – is

used as the “virtual cathode” point. Pins 4, 6, 8, and 1 are NC on 2A3 octal

base tubes, just like they are NC (not connected) on 6B4G tubes (as a matter of

fact, the octal base of the 2A3 octal is identical to the 6B4G base). Thus when

a 2A3 is plugged into the socket, it is indifferent to the connection of these

pins.

How to make it all work?

Both tubes have 2.5V heaters with similar current

consumption, and 15W anode dissipation ratings. But the bias voltage of the

2A3, i.e. the potential of the cathode in respect to ground, is much higher

than that of the 1619. At the foreseen operating condition of approximately

250V across the tube and (exactly) 60mA of current draw, the bias voltage of

the 2A3 exceeds the ratings of the LM317 regulator. While this could be solved

by adopting a TL783 regulator which is safe for input voltages of up to 125V

(the main and probably only relevant difference between these two regulators is

the adoption of a DMOS output transistor in the TL783) – the bias voltage times

the current draw will require a relatively large heat-sink and lead to a

potential overheating problem. The resistor shown in the schematics absorbs

most of the voltage differential and lowers heat-sinking requirements for the

active element (LM317), leading to more stable operation. I just somehow prefer

to run solid state components as cool as possible, and leave the heat to the

high power ceramic resistors. In order to operate the 1619 tube, the resistor must

be excluded from the circuit, which is easily done bypassing it with a switch.

The difference in voltage across the tube will be dealt with

naturally by the difference in tube type: since the 1619 is a tetrode, the

total current draw is the sum of anode and screen grid current. Thus anode

current will not be 60mA as with the triode 2A3, but about 54mA – as

approximately 6mA will be drawn by the second grid. Changing tubes and

excluding the voltage dropping resistor by switching it off will lead to a

different set of operating conditions which suits the 1619 just as well as the other

set of operating conditions (with voltage dropping resistor) suits the 2A3.

The output transformer

Another important difference between 2A3 and 1619 is the

optimal anode load: while the 2A3 triode will perform at its best at values between

2.5k to 3k, the 1619 beam tetrode would require a load between 5k and 6k. To

achieve this goal, we need a very versatile output transformer which would

allow us to change anode loading at the flip of a switch (or switches).

The Lundahl LL1623 output transformer used in this

amplifier, besides the highest build and materials quality, has a probably

unique versatility and adaptability to various circuits, since both the primary

and the secondary windings can be arranged to suit a wide range of currents and

transformation ratios.

While the primary windings could be arranged in parallel to

double the maximum current capability, this would lead to lowering the

inductance, and since the gap is already set at the factory to suit for 60mA,

90mA, or 120mA of DC current across the primary – the best solution is to connect

all primary windings in series, as shown in the datasheet. Thus the inductance

of the primary will be defined by the chosen gap, i.e. required DC current

value. Quite logically, the optimal gap for the RH2A3 amplifier is as set for

60mA DC current across the primary.

The secondary windings can be combined to achieve standard

foreseen anode loads of 1.6k, 3k, and 5.6k – for an insertion loss that varies

between 0.2dB and 0.8dB. Bearing in mind that all the above combinations are

possible for 4, 8, and 16 ohm loudspeakers – it is obvious that the possible

anode load is actually even more varied.

While the user might exercise his (or her) wits by finding

alternative connection possibilities, an application sheet is available on the

Lundahl site showing possible secondary winding connections that allow

switching between “adjacent” anode loads by use of switches or bridges. Since

my application is with 8 ohm speakers, I have chosen to prepare the output

transformers for B/C, i.e. 5.6k and 3k loads into 8 ohm outputs.

While for the connections of the primaries I have chosen to

solder pieces of wire, the much more elaborate secondary connections seem to require

a different approach: hence the wire harness showed in the pictures. The three

switches allow the choice between 3k anode load (suitable for 2A3) and 5.6k

anode load (suitable for 1619). While the wiring harness looks complicated, and

indeed requires a couple of hours to complete and check – there is no need to

rush while building an amp. The building experience is indeed a source of

pleasure, and once you finish building the amp, you will probably be using it

for years to come: what would be the point of building it in one afternoon?

I feel confident with the solution I have adopted – but a

further simplification and expedient could be a custom PCB, foreseen to be

simply mounted and soldered on the pins of the secondary windings, greatly

simplifying the build and avoiding the need to check and re-check.

Thus, to recapitulate: one switch to include/exclude the

voltage dropping cathode resistor (2A3/1619) and three switches to select the

optimal anode load for the tube (3k/5.6k). I guess that is not too much to do

in order to enjoy two (slightly) different amplifiers from a single box?

Of course, the switch for the dropping resistor can be

omitted if TL783 is used with an adequate heat-sink (dissipation will reach

2.5W with 2A3 tubes) – and with that touch the only possibility for error would

be avoided: because, if you insert a 2A3 tube without the voltage dropping

resistor, you will most probably kill your LM317 – and if you insert a 1619

tube with the voltage dropping resistor in circuit, it will not be able to draw

the specified current, leading to possible overvoltage conditions for the power

supply caps (which is why those are not rated for a tempting 400V that looks to

be just fine, but would be easily exceeded if the output tubes do not draw

current for any given reason). On the other hand, if you forget to set the

correct load for the output tubes, the lack of power and early clipping will

harmlessly remind you to check the switches…

How does it sound (and compare)?

I used to have for quite a long time a 6B4G SE “no feedback”

amp that I enjoyed quite a lot and used it as a “reality check” at the time of

the initial RH designs – RH84 and RH807. The amp was very straightforward and

classic, I had conceived it as a two stage design with 6SN7 (grounded cathode,

bypassed cathode resistor, resistor loaded anode, 6mA current) driver and 6B4G

output (automatic bias via bypassed cathode resistor, 300V across the tube,

50mA current draw, 3.5k load). While the “no feedback” designation is a

nonsense per se – as particularly in triodes, plate current is dependent on the

plate to cathode voltage differential: as the signal tries to pull the control

grid positive it causes a rise in anode current, but the anode to cathode

voltage differential decreases at the same time, trying to pull the anode

current down. Since anode and control grid are pulling in opposite directions,

this is negative feedback by definition… (to put it as straightforward as

possible, though simplified to the point of easy criticism) While the behavior

of the triode suggests an “inbuilt” feedback mechanism, the term “no feedback”

is more of a common lingo expression reflecting the fact that cathode

degeneration was “avoided” throughout by adoption of bypass caps on cathode

resistors (avoided, that is, from the high pass frequency on), as well as the

lack of NFB either local or overall. While the feedback nonsense should be left

aside, the reality check comparison

is something I frequently do, and can only suggest it to everyone – as a means

of avoiding the proud of ownership (or craftsmanship, or own design) syndrome

and illusions about the perceived quality or quantity. The mentioned amp was a

classic 3.5W 2A3 class amp (with good quality black anode 6B4G tubes) and

represents a valid statement to compare the performance of the RH2A3 with.

One important detail is the hum inherent with AC heating

operation of direct heated tubes: the hum level is proportional to the heater

voltage, and the gain of the tube. Thus the most obvious advantage of the 2A3

in comparison with the 6B4G is AC related hum. In RH amplifiers, hum is

obviously reduced by the application of feedback – so much so that it can be

barely heard on the RH300B (5V heaters), and it becomes virtually inaudible on

88dB/W/m speakers with 2A3 tubes (2.5V heaters). On the other hand, the hum of

a “no-feedback” 6B4G amp can be easily heard on the same speakers, although it

might not be so distracting at the listening position (“humming pot” or not, it

could be heard between songs during quiet night hours). If a 6B4G is used

instead of 2A3 in this circuit, AC hum would be more apparent, but much less

pronounced than in a classic “no-feedback” circuit.

First of all, the power output of this amp is nothing short

of awesome, from a 2A3 amp – that is. While 5W will not rock most houses

(unless those houses are equipped with very efficient speakers), it definitely (re)produces

music much louder than a classic 2A3 amp – to the point that, depending on your

listening taste, you would probably not need anything more powerful 95% of the

time, even with 88dB/W/m loudspeakers. Obviously, the RH300B can go much louder

– and does so effortlessly after the point where the RH2A3 clips – showing that

there is a definite difference in output power, quite adequate to the 5W vs.

12W comparison.

This gap in power is reduced when 1619 tubes are used. While

lacking good models for the 1619 I can only estimate the power to be about 7.5W

– and the best comparison probably is the RH307A Super. While the curves of the

307A look more promising than those of the 1619, both are 15W anode dissipation

tubes, and the difference in curves probably stems as well from the difference

in internal construction – while the 307A is a direct heated pentode, the 1619

is a direct heated beam tetrode. The direct comparison shows similar power for

both amplifiers… which is quite logical to me. Thus the option to use 1619

tubes does extend the possibility to enjoy music with this amplifier.

In operation, what makes this amplifier so nice and user

friendly is current consumption and heat. If you sum up the requirements for

the various secondary windings on the power transformer, it becomes apparent

that a nice 100VA unit will be just fine for the task – which translates into

nice and small, particularly in the realm of toroids. Not to mention further

size decrease if you choose to wind two transformers, of which one for the tube

heaters (allowing easy and cheap modification to use i.e. 6B4G output tubes).

Current draw is slightly less than 140mA, allowing you to employ a nice

smallish choke… while the schematics calls for a 10H 150mA choke, I have used a

5H 150mA unit without any ill effects (like hum). Cold and relaxed in

operation, particularly when compared to larger amps, you can just forget about

it once you have powered it up, and concentrate on the music (or whatever else

you are doing that is just being complemented by the music).

How about the sound? While the amplifier quite predictably

sounds remarkably similar to other RH amplifiers, it does present some unique

characteristics due to the very high quality of the output transformers used.

While the socket play is an interesting feature, in a way the amplifier is

built around the LL1623 output transformers – allowing for easy adaptation to

the optimal load for each tube used. The low insertion loss and high intrinsic

quality of the transformer are clearly felt in the sound, compared to other

good quality and large size, both EI laminations and double C (4C in fact – it

should be called quadruple C, I guess) core output transformers used in the

RH300B and RH307A, respectively.

An initial premise about the sound in the 2A3 version is dictated

by the specific output tubes. Since I am not aware of other 2A3 octal base

tubes beside the Shuguang, this is probably a limiting option for tube rolling

and synergistic combinations. The “old type contemporary” double anode 2A3

tubes are probably inferior in quality to the best contemporary “mono-plate”

2A3 tubes, and the “fake mesh” 300B (most probably made in the same factory)

which were sold under various brand names during the years, and are known for a

specific sound signature favoring great highs and mids. The RH2A3 (with 2A3

tubes) sounds remarkably similar to the RH300B, albeit with lower power.

Besides unexpectedly high listening volumes when compared to other 2A3 amps,

the most striking points are great, well defined, and extended bass notes – as

well as great mids, particularly lower mids. We could say that the amplifier

does a great performance in the “melody range”. Differing from the “fake mesh”

300B, the RH2A3 sounds more similar to the sound of the RH300B used with EH300B

tubes – but the bass is even better defined, the mids finer chiseled: I guess

that with the extreme similarity of the schematics, and with the same or very

similar drivers used, as well as the same rectifier tube, the merit clearly

goes to the Lundahl LL1623 output transformers, easily outperforming the nicely

wound and rather large (and heavy, too) EI105 lamination output transformers

used in my RH300B. This is an assertion that I hope to check in the future by

substituting the output transformers in the RH300B.

The 1619 is a direct heated beam tetrode, and beside an

increase in power, few would expect it to introduce an improvement in sound

quality… but as a matter of fact, it does. Compared to the Shuguang 2A3 octal

tube, the black metal 1619 tubes are visually inferior, but their sound is

better balanced overall. While the bass is slightly less pronounced, it is by

no means inferior due to the increase in power – but the most striking

difference is less pronounced mids, and an improvement in upper mid and highs quality.

The mids are less in evidence, and the general tone is even more listenable and

involving. Output power is on a par with the RH307A Super, and comparing to the

large 4C output transformers in that amp, the LL1623 shows even greater finesse

in the upper mids, a clearness of tone that becomes particularly apparent when

listening to LP records. When clear and clean upper mids are mentioned, the

first thing that comes to mind is a possible exaggeration of these tones when

vinyl is reproduced – but it is quite the opposite, as the upper mids and highs

are not exaggerated at all, while the impression is one of increased listen-ability.

The upper mids and highs result extremely clear and clean, not intrusive or

evidenced.

What if?

As already mentioned, the only 2A3 octal base I know of are

the older production Shuguang made specifically for Audio Innovation, which one

might already own, or find a means to acquire somewhere. On the other hand, the

1619 is basically a sleeper tube – visually unattractive, odd heater voltage,

direct heated, and commanding relatively low prices (mostly driven by the radio

collectors market). Besides the possibility to opt for building it as a classic

UX4 socket amp – which is always a good solution per se, but leads to a loss of

1619 functionality – one possibility could be adopting UX4 to octal adapters,

similar to those employed to make use of 5Z3 tubes in octal sockets.

Making such

an adapter should be very simple and straightforward once you procure the parts

necessary – after all, it is about soldering wires between the correct pins,

and fastening the two parts together – and it would allow to listen to the amp

with modern 2A3 tubes as well as the highly regarded mono-plates of times long

passed. I guess employing adapters would

be much easier than changing the bases on 2A3 tubes (once you unsolder the pins

and dilute the “glue”, it is easy to detach the base on any given DHT… all you

would need to do would be fitting the wires into the proper pins on the octal

base, gluing the base and soldering the pins. A good option to glue the base

could be thermally stable silicone (for heating applications)… but that might mean

pushing it too far, for most!

Another very simple alternative would be to build the amp

for 6B4G tubes, which can still be found at low and affordable prices (Russian

6C4C – i.e. 6S4S) – and use 6L6 tubes as an alternative. By 6L6 tubes I mean

specifically the metal 6L6Y, the glass ST version 6L6, and the several Russian 6П3С, i.e. 6P3S

types – all those 6L6 types are rated between 15 and 19W anode dissipation,

thus perfectly suitable to be used in the circuit instead of the 1619, not to

mention the possibility to employ 6V6 and 6F6 types as well – and all that with

just a few circuit differences (simple modifications to be performed on an

already built RH2A3-1619) as shown in the schematics.

Besides 6.3V heater windings for the output tubes (6L6 types

draw 0.9V which is almost identical to the 1A drawn by the 6B4G), the main

difference is the cathode connection: instead of choosing between keeping or

excluding the resistor in the circuit, this time it is about choosing between

“virtual cathode” (made on pin 6 – which path includes the voltage dropping

resistor) or indirect heated cathode (on pin 8). Pin 1 can remain connected to

ground, thus the metal envelope on 6L6Y tubes will be grounded, and EL34 tubes

might be used as well with their g3 correctly grounded via pin 1.

I would like to thank Mr. Per Lundahl of

Lundahl transformers, Sweden, for his kind assistance, help, and support in the

realization of this project.

Hi Alex,

ReplyDeleteInteresting article. I Have some white label, double plate, 2A3 octal. I think it must be Suguang, but there are no signs on the glass. Just only '2A3' .

Just to be shure: these tubes works on 2,5 V heater voltage ?

Bye, Hans.

Hi Hans,

DeleteIf you are sure that it is 2A3 on octal socket, not 6B4G - it will operate on 2.5V heaters.

You can always try to see if the heaters will light up on 2.5V: this will not damage a 6B4G but on it the heaters will not light up... and you will know for sure. There are no 6B4G marked as 2A3, anyway.

If you have more questions, please e-mail me.

Regards,

Alex

Just finished building this amp to spec with 6b4g AC heated. The amp is sensational. Didn't know the 2a3 family could sound so full and satisfying. Listening on 90db full range speakers with very minimal hum only within a foot or two of driver. Thanks Alex for publishing this marvelous amp!

ReplyDelete